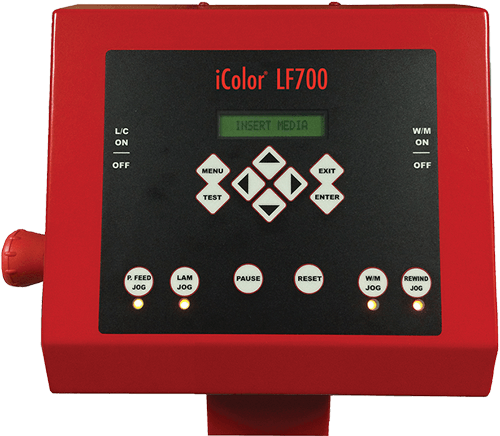

The IColor® LF700+ combines the latest tracking technology with robust, industry standard engineering. Impressive speeds and precision registration allows the user to produce short run labels with reliability and at the lowest cost. It enables you to provide your customer with a complete digital printing and finishing solution. A "must have" for either established label printers or end users wishing to create their own in-house labels.

UNINET® introduces the IColor® LF900, an exceptional INTEGRATED WIDE FORMAT LABEL finishing solution developed to manage an extensive variety of wide format label media stock featuring lamination, contour cutting, waste matrix removal, slitting and final rewind. The UNINET® IColor® LF900 was created to optimize the label finishing process on demand.

The UNINET® IColor® LF 200 is a compact digital label finishing system incorporating lamination, die cutting, slitting, waste removal and final rewind capabilities. It combines lightweight versatility with heavyweight performance to provide seamless finishing for any type of short-run label production.

This machine allows die-cutting without an operator on adhesive sheets and digital prints on cardboard, silk-screen prints and print shop materials.

UNINET® presents the Digital UV Coater, a cutting-edge and versatile UV/Aqueous Coating System that provides on-demand digital printing with a quick and effective solution to apply a clear protective coating to printed, roll to roll or cut sheet labels and up to 10" wide by nearly any length.

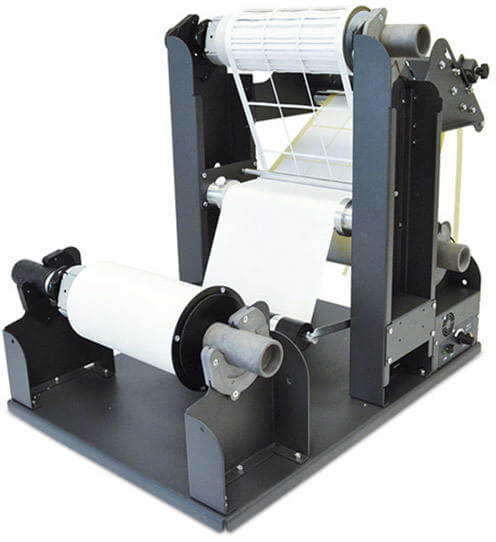

The IColor® Matrix Remover and Slitter can unwind, remove the label matrix from a die cut label, roll, slit thanks to one or more cutter blades, and rewind onto a 3" motorized core holder rewinder.