Experience the cutting-edge

UNINET® DTF™ 4300

A high-performance, inkjet-based digital direct-to-film transfer printing technology designed for medium to large-scale industrial garment decorating production. Unlock unparalleled efficiency and versatility for creating vibrant and industrial quality DTF™ transfers to apply onto light and dark-colored garments.

Elevate your garment decoration game like never before! Leverage the expansive 17” wide roll feed system printing capability to print your designs onto a wide array of garments, accessories, and other products. Let your creativity run wild and produce stunning industrial-quality and customized apparel that will impress your customers.

Seize the Potential of a Dual Business Model Opportunity.

Unleash boundless growth potential with the UNINET® DTF™ 4300. Expand your offerings and venture into lucrative new product lines, yielding higher margin returns.

- Monetize your digital transfers: Print and store thousands of designs for lucrative sales opportunities down the line.

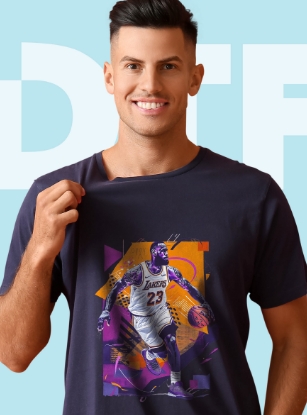

- Profit from Fashionable Apparel: Print and press to create marketable finished products, such as t-shirts and other garments.

Revolutionize your Printing Process with Boundless Applications.

Whether you’re creating simple, intricate, or colorful masterpieces, our UNINET® DTF™ 4300 printer delivers A2+ sized dazzling weedless digital transfers in a single pass.

- Print and transfer on a wide variety of dark or light-colored fabrics, such as cotton, polyester, spandex, vinyl, nylon, leather, canvas, linen, chemical fiber, and more.

- Create stunning and fashionable t-shirts, dresses, backpacks, caps, tote bags, decoration pillows, tennis shoes, sports performance gear, and more.

- Produce long-lasting, flexible, soft-touch, vividly colored digital transfers.

- Experience fast and cost-effective print production and automation with flawless results.

Variety of Options for Ultimate Versatility.

Harness the flexibility of the DTF™ 4300 Transfer printing system, which conveniently integrates with our UNINET® DTF™ Slim Shaker or the DTF™ Horizontal 17, available in 17” and 24” widths.

Now, you can choose your Shaker equipment based on your business needs; these automated powdering and curing units, when combined with our DTF™ transfer printers, ensure flawless and uniform adhesive powder coverage for vibrant, durable, and stretchy prints. Also, with this configuration, you may optimize your DTF™ production with the ability to produce roll-to-roll job runs for increased efficiency on a large scale.

Maximize your Printing Potential to New Heights.

Garment printing professionals can take their ideas from concept to finished product much more quickly with UNINET®’s full-functional DTF™ product line, which includes printing technology, dedicated RIP Software, consumables, transfer films, transfer powders, cleaning solutions, and more.

Don’t miss out on the opportunity to elevate your garment decoration business printing capabilities – invest in the UNINET® DTF™ 4300 now and take your creations to the next level!

Some Key Features:

- Accepts DTF™ rolls up to 17” wide.

- Vacuum-enhanced printing area for better ink adhesion and avoidance of film buckling.

- WICS (White Ink Circulation System) to minimize clogging.

- Two high-definition industrial-grade inkjet Printheads.

- Continuous XL Ink Tank Feed System.

- Humidity Sensor.

- Driver Software.

- Optional full automation capable when bundled with a shaker.

Superior Quality Dual Printhead Technology.

Boasting its industrial-grade dual print head design and tiny dot gain, The UNINET® DTF™ 4300 printing system can produce high-definition prints and excellent color fidelity. Using a combination of five inks, which considerably increases the number of colors conceivable, this technology uses an automated process to lay down layers of CMYK colors and print white as overprint, all in a single pass, resulting in professional, unrivaled print quality and sharpness.

Printing System Includes:

- UNINET® DTF™ Advanced RIP Software features exceptional file preparation, white and color management, production automation functionality, and more. (Built-in Ethernet Port on PC is Required).

- 2-hour virtual onboarding (soon to be replaced or enhanced with the UNINET® DTF™ Master Class Video Training Series).

- UNINET® DTF™ Five-color Inks- 1000 ml bottles.

- UNINET® DTF™ Transfer Powder 2x 1.75 ml bottles.

- UNINET® DTF™ Transfer Film Roll – 328 Ft Roll.

- UNINET® DTF™ Starter Bundle (Hygrometer, Maintenance Solutions and Accessories).

- World Class Service and Support direct from UNINET®.

- UNINET® USA 12-month warranty.

Stunning Total Worth!

12 Month Warranty: UNINET offers a 12 month warranty which pertains to replacement of faulty materials during the first year from the date of purchase of the machine (except for damage caused by the user, or other circumstances that does not depend on manufacturing defects, including lack of maintenance and clogs). Consumable parts are excluded from the warranty, such as: Ink, print heads, capping stations, dampers, control boards, cables and waste bottles (except in cases where the product is DOA), and does not extend to any UNINET Hardware Product from which the serial number has been removed or that has been damaged or rendered defective as a result of accident, misuse, liquid spills, abuse, contamination, improper or inadequate maintenance or calibration, or other external causes (such consumable parts are available as spare parts if needed). This includes all electronic boards, cables, power supplies and the like - liquid or ink spills of any kind can short one or all of these items. Lack of use for more than a day or two can cause the ink to clog and lead to longer maintenance cycles, possible print defects and need to replace a consumable that is not covered under warranty. Shipping costs to UNINET for warranty repair are the responsibly of the user. For full warranty details – please register your product on our website ( https://www.icolorprint.com/warranty ) or contact us to request a copy.

The price of this printing equipment includes onboarding and training. Onboarding will be replaced or enhanced with the UNINET® DTF™ Masterclass (when available), followed by a one-hour virtual review session with a technician. If you find that you will need more support to get set up and operational, it will be provided upon request. Because this printer is ink-based, it requires continual use. The lack of use of this equipment for more than a day or two or non-adherence to maintenance or cleaning procedures can cause the ink to clog and lead to longer maintenance cycles or possible print defects.

What’s NOT Included, But You May Need:

- Windows® 10 or higher computer (PC) with an available Ethernet port. If a network port is not available, a separate USB gigabit ethernet adapter will need to be purchased.

- Heat press for finishing (curing) the final print - We recommend a 16”x 20” heat press.

- A humidifier (to keep the humidity above 40% in the print room) is recommended.

- Five small funnels (for ink filling).

- Personal Training and Technical Support*.

- Protective gear.

- Air purifier/fume extractors and ventilators are used for the curing process.

WARNING:

WORK IN A WELL-VENTILATED AREA and use protective equipment when working with DTF™ products and processes. UNINET® highly recommends the use of a fume extractor to handle the fumes caused by TPU adhesive powder curing. We recommend body protection, including the use of PPE equipment such as a full body covering, a respirator or N95 mask, goggles, and gloves, to protect against TPU adhesive powder (prior to curing) that may become airborne due to handling. Inhalation of TPU adhesive powder or fumes may be hazardous to your health. The use of DTF™ equipment, chemicals, powders, inks, and all accessories is at the user’s sole risk. DTF™ equipment is intended for use in a commercial environment. UNINET does not recommend the use of DTF™ equipment in a residential or in-home setting. For DTF™ inks and film, we highly recommend a humidity environment of over 50% to minimize the risk of ink clogs and film buckling.

Easy

to Use

High

Efficiency

Intelligent

Printing

Auto

Feeding

Auto

Rewinding

Different kind of fabrics

PRINTING SYSTEM TECHNICAL SPECIFICATIONS

- PRINT SPEED: up to 44 - 50 square ft / hr (~20 A2 pages/hr)

- RESOLUTION: Up to 1440 dpi

- PRINTHEAD: Dual system

- OPERATING SYSTEM SUPPORTED: Windows® 10 & Windows® 11

- INTERFACES: Ethernet Port

- PAPER CAPACITY: 328 ft transfer film roll: 17 inch wide

- RATED CURRENT: 7A

- FILM ROLL SIZE (MIN / MAX): 17 inches

-

DIMENSIONS (WxDxH) (Printer Only):

Uncrated - 53” x 35” x 53” - Crated – 67” x 32” x 23” - WEIGHT: Uncrated - 286lbs / 130kg - Crated: 375lbs / 170kg

- POWER: 120V