A New Fashion Icon for Printing.

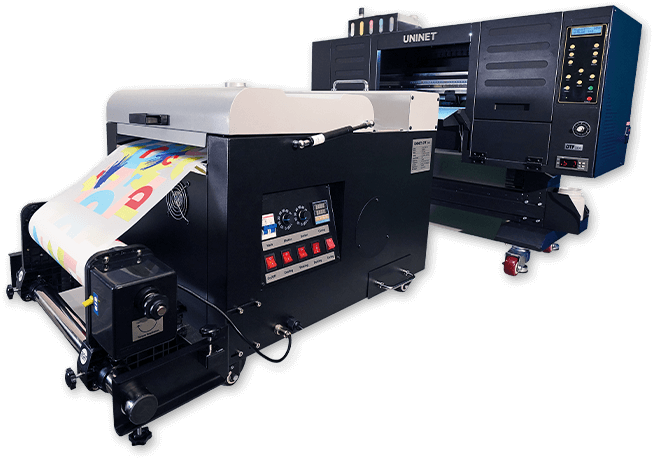

Meet the UNINET® DTF™ 3300, the inkjet-based digital and direct-to-film transfer printing system for medium to high-volume production of digital transfers for light and dark-colored garment decoration. The new fashion icon for garment decoration is out, regardless of the season!

Printing Shop or rather "Atelier"?

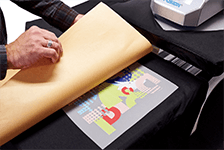

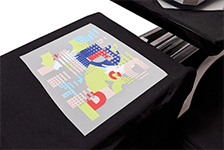

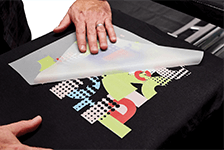

One thing is for sure: with this powerful, space-saving 13" wide format printing equipment, you can print on transfer film paper and heat transfer your designs onto a broad range of garments, accessories, and other products, allowing you to produce stunning industrial-quality and customized apparel while at the same time elevating garment printing to an art form.

Productivity and quality now sharing the catwalk.

A Dual Business Model Opportunity.

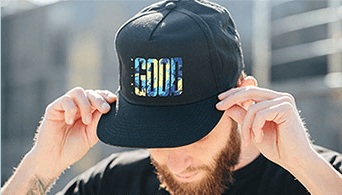

With the UNINET® DTF™ 3300, you now have plenty of runways for growth by meeting at the intersection of the highest productivity and quality. You may offer both digital transfers (including printing thousands of heat-transfer designs that can be cut and stored to sell later) and fashionable apparel (including printing and heat pressing to sell your finished product, such as t-shirts and other garments). Two ample business opportunities, one a top model. Welcome to the world of the UNINET® DTF™ 3300.

"Couture" or "Ready to Wear" mode. Totally up to you.

The UNINET® DTF™ 3300 allows you to produce simple or complex, colorful weedless digital transfers in one pass. Print and transfer on a wide variety of dark or light-colored fabrics, such as cotton, polyester, spandex, vinyl, nylon, leather, canvas, linen, chemical fiber, and more. Create digital transfers that are stretchable, durable, soft-handed, and vibrant in color. It is not just lightning-fast but also cost-effective print production and automation, especially for high-volume apparel production. It delivers superior-quality transfers with excellent elasticity and stretchability, high durability, and brilliant colors.

On walking the catwalk and talking the talk.

The UNINET® DTF™ 3300 gives you the tools you need to expand and grow your apparel decorating business and branch out into new product lines for higher-margin returns. It combines a transfer film printer with an automated powdering and curing system to produce the most stretchy, long-lasting, gentle-to-the-touch, and brightly colored digital transfers possible. Go ahead: Dream up your fashion lineup and make it happen the UNINET® DTF™ 3300 way!

Superior Quality Dual Printhead Technology.

With its dual print head design and tiny dot gain, The UNINET® DTF™ 3300 printing system can produce high-definition prints and excellent color fidelity. Using a combination of five inks which considerably increases the number of colors conceivable, this technology uses an automated process to lay down layers of CMYK colors and print white as overprint, all in a single pass, resulting in professional, unrivaled print quality and sharpness.

The UNINET® Seal of Quality.

Every UNINET product introduced to the market is supported by the UNINET seal of quality, which has made the company one of the world's most trusted printing solutions providers for many years. The same is true for the UNINET® DTF™ 3300. In the form of consumables, transfer film papers, and cleaning solutions, UNINET offers a comprehensive, all-inclusive functional solution to streamline the printing process and empower printing professionals to rapidly move from thoughts to see their creations come to life.

The UNINET® DTF™ 3300 Printing System comes equipped with the following:

- UNINET® DTF™ 3300 Auto-Powder Unit

- Two high-definition inkjet Printheads

- UNINET® DTF™ ProRIP™ Advanced RIP Software features exceptional file preparation, white and color management, production automation functionality, and more.

- UNINET® DTF™ Master Class Video Training Series: Discover everything there is to know about DTF™ printing, maximize the value of your equipment, and be inspired to expand your business even further.

- UNINET® DTF™ Five-color inks – CMYK+W

- UNINET® DTF™ Powder

- UNINET® DTF™ Film Roll – 100 meters

In addition, the printing system features:

- Two high-definition inkjet Printheads

- Ink tanks with Continuous Feed System

- Printer Roll Feeder with auto-feeding capabilities

- Heavy Pressure Roller to ensure the printing paper's precision and stability.

- Auto-Rewinding capabilities

- White Ink Circulation Motor (helps circulate white ink)

- Bluetooth Humidity and Temperature Sensor

- Built-in Heater (enhances ink adhesion and curing)

- Internal Controllable Vacuum Suction (prevents film buckling)

Beyond this, UNINET® provides.

- UNINET® DTF™ Cleaning Solutions

- UNINET® DTF™ Inks

- UNINET® DTF™ Transfer Films

- UNINET® DTF™ Powders

- USA Training and Technical Support*

- UNINET® USA Warranty

*Onboarding Technical Support included in USA and Europe; additional technical Support requires purchase or a subscription plan.

What's NOT Included, but you may need:

- Windows® 10 or higher computer (PC) with a DEDICATED Ethernet port (the ethernet cable runs directly from the PC to the printer)

- Heat press for finishing (curing) the final print - We recommend a 16" x 20" heat press

- Humidifier (to keep the humidity above 50% - 65% in the print room) - recommended

- Personal Training and Technical Support*

- Protective gear

- Fume extractors and ventilators

NOTE: This equipment requires a well-ventilated area with a filtration system. When working with DTF™ products and processes, use protective gear since fumes might be harmful. DTF™ inks and film/sheets need an adequate humidity environment - above 50% - 65% humidity is strongly advised to reduce the possibility of ink clogs and film buckling.

Printer Technical Specifications

Printer

- Print Speed: 15 - 30 square ft / hr (~11 - 22 A3 pages / hr)

- Resolution: Up to 1440 dpi

- Printhead: Dual system

-

Operating System Supported:

Windows® 10 & Windows® 11 - Interfaces: Ethernet / Gigabit LAN - Requires a DEDICATED Ethernet port (No wired network can be used, the ethernet cable runs directly from the PC to the printer)

-

Paper Capacity:

Transfer film roll: Up to 13 in / 330 mm wide X 328 ft / 100m long - Rated Current: 5A

- Rated Power: 500W

- Dimensions (WxDxH): 42 x 26 x 37 in / 107 x 65 x 95 cm

- Weight: 110 lb

- Power: AC 110/60Hz

Auto-Powder Unit

-

Powder Feeding Control:

Automatic powder application, heating/drying -

Powder Shaking Speed & Intensity:

Adjustable - Rewinding Function: Film take-up automatically

- Heat Curing Technology: Infrared heating tube

- Heating Temperature Range: 0-300℃

- Rated Voltage: AC 110 / 60Hz

- Rated Current: 10A

- Rated Power: 1800W

- Machine Size (Min / Max): 34 x 26 x 24 in / 85 x 65x 60 cm / 850 x 560 x 600 mm

- Weight: 97 lb / 44 kg